We have an extensive worldwide network of experienced and qualified personnel.

Our process and systems afford us the ability to provide customized solutions for your Project Management and Project Quality requirements. Our customers can count on our industry knowledge and technical experience to mitigate the probability of having low quality and non-compliant products.

We Provide Solutions!

BIMIS has a worldwide network of experienced and qualified inspectors and surveyors. We provide customized solutions for your Project Management and Project Quality requirements through our tested and proven processes and systems.

Our customers can rely on our technical knowledge and industry experience to mitigate the probability of low quality and non-compliant products.

BIMIS – Providing service in Upstream, Mid-Stream and Downstream of Oil and Gas Projects, EPCM, Chemicals, Mining and Utility industries

Project Quality Consultancy

BIMIS can help your Project teams develop, implement, and maintain a Project-specific Quality Assurance and Quality Control program.

We are the trusted experts in developing Project Quality plans, Project QA/QC procedures, Inspection & Test Plans (ITP), Audit plans and checklists for meeting the Project objectives.

Supplier Audits and Assessments

Our Supplier Audit and Assessment Program is intentionally designed by leveraging its broad network of qualified auditors and Subject Matter Experts (SMEs).

We also understand the importance of developing audit programs as per Project requirements and prescriptive assessment criteria.

BIMIS has the experience and knowledge to assist in establishing in-house audit programs.

Equipment Criticality Assessment

Inspection and Quality Control should not be used to mitigate the risk of an inadequate design.

Equipment design has a significant impact on life cycle cost and quality. It is imperative to identify the appropriate equipment engineering criticality level during the design stage to determine the most suitable inspection plan in order to meet Quality expectations.

BIMIS can provide an independent review, verification, and equipment criticality plan for your Projects.

Project Kick-Off Meetings & Pre-Inspection Meetings

BIMIS Project Coordinators and Project Managers can support the Customer’s Project team in facilitating Kick-Off Meetings and Pre-Fabrication Meetings most effectively, especially in remote locations where physical visits are challenging.

Working on behalf of the Customer, we can prepare the meeting agenda, conduct the meeting, close out the meeting, and communicate the outcome to the Customers.

Inspection

Planned and systematic inspection significantly reduces risk and related cost due to rework, manufacture/construction impact, warranty costs, customer complaints, time and money spent on failing products, and eventually a loss of market share.

BIMIS Inspection services are focused on inspecting and verifying product quality, reporting, and informing the customer in advance regarding the risk of delivery with deficient products. We also verify equipment compliance to applicable code, drawings and specifications.

Our inspection procedures and policies are centered around assisting both the buyer and the manufacturer. We are focused on Quality product, minimizing risks, and developing a sustainable business relationship with all parties.

BIMIS Inspection personnel ensure all products are within specifications with minimum to zero defects and that they are fit-for-purpose resulting in customer satisfaction.

Witness of Factory Acceptance Test (FAT), Site Acceptance Test (SAT)

Considering the cost and delays caused by repair and rework at the construction site, it is always better to ensure full functionality and Quality prior to shipment to site. Fabricated process equipment can be incredibly complex which results in an increased risk of errors. Factory Acceptance Testing (FAT) at the Original Equipment Manufacturer’s facility helps to verify that the equipment is fit for purpose. FAT testing also ensures the equipment fully complies with the Purchase Order scope including specifications, drawings, datasheets, ITPs, applicable Codes, FAT checklists and procedures as specified.

BIMIS’ professional team can coordinate and witness FATs for all types of manufactured and packaged equipment. Subsequent reporting to the Project team with any observations and/or findings.

Welding Engineering Consultancy

The BIMIS Welding Engineering and inspection team is fully qualified with certifications such as AWS, CWB, TWI/CSWIP. Our Welding Engineers can support Projects in design review, welding requirements, supervising welding teams on Projects, reviewing welding procedures, facilitating welding procedure qualifications, and preparing welding procedures to assist the fabrication and welding teams. BIMIS also conducts detailed Root Cause Analysis (RCA) investigations and failure analyses on significant Quality issues.

Coating & Painting Inspection

Coating and painting increase the lifespan of critical process equipment extensively used in Oil & Gas facilities around the world. Prescribed inspection of coating and painting activities prevents future damage, thereby assuring a safe workplace which is a key objective. BIMIS painting and coating inspectors are NACE certified.

BIMIS conducts verification of coating material and equipment, consumable storage and certification, qualifications for coating processes, surface preparation, checks cleanliness and profile, wet and dry film thickness, visual, color coding and painting, adhesion testing, visual inspections before/after surface preparation and before/after application of each coating layer, and surface contamination.

Failure analysis and facilitating Root Cause Analysis investigation report and procedure review, assisting Clients in application, test procedure and Inspection and Test Plan, and field Laboratory Test.

Preservation, Maintenance (P&M) and Storage inspection

In industrial facilities, preservation and maintenance (P&M) define structured routines, schedules, procedures, and process actions to keep valuable equipment safe and sound. It helps ensure the equipment is safe and any applied preservation as per the Original Equipment Manufacturers (OEM) preservation procedures.

BIMIS employ P&M Inspection specialists to help support your Projects.

Equipment and services

BIMIS has extensive and proven experience with inspecting all forms of process equipment.

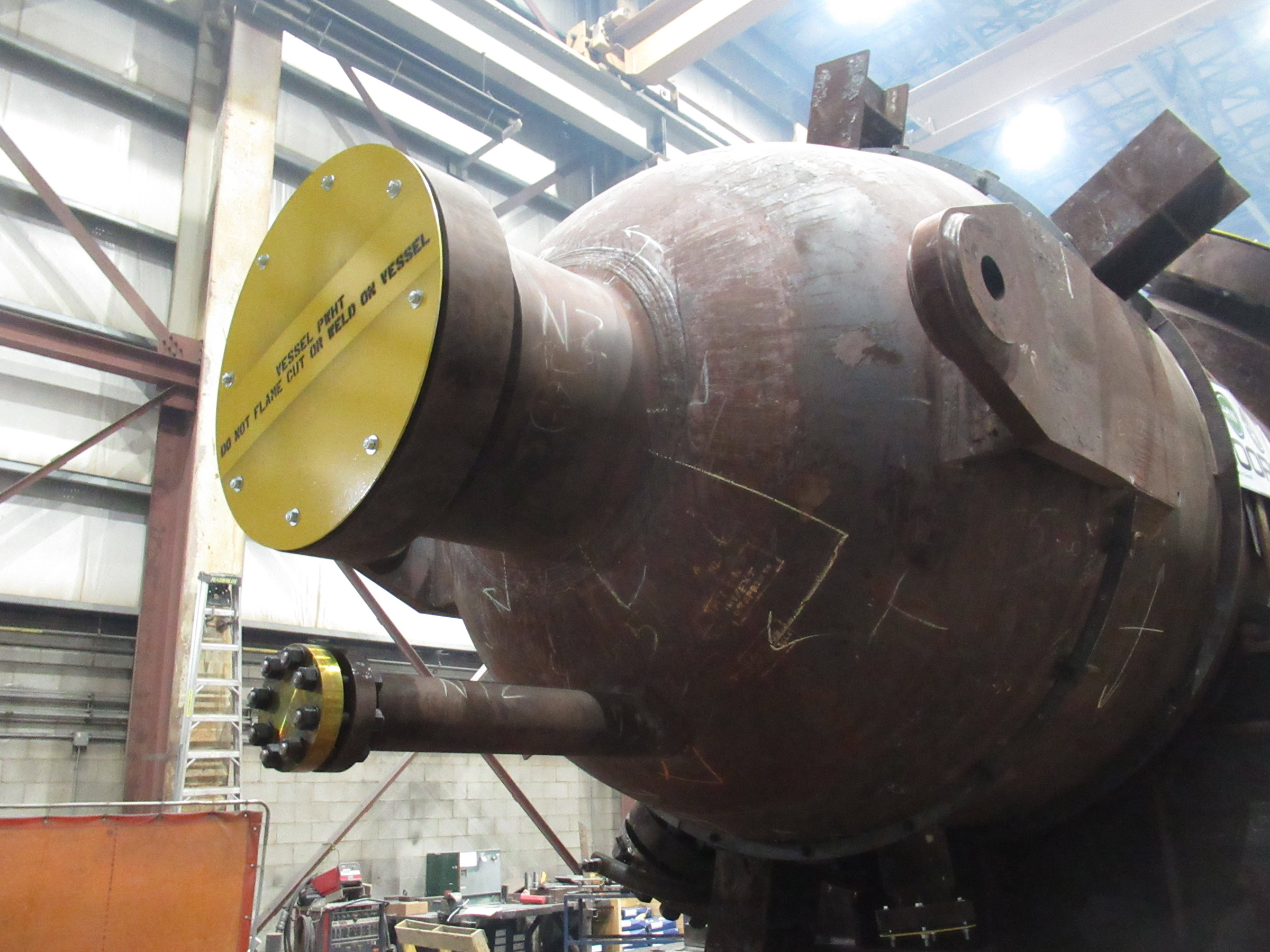

Static Equipment

Pressure Vessels and Boilers

Storage Tanks

Process Piping Systems

Process Heaters

Heat Exchangers

Incinerators and Loading Arms

Expansion and Flexible Joints

Pig Launchers and Receivers

Linings and Flanges

Line Pipe

Fitting

Rotating Equipment

Pumps and Compressors

Belt Conveyors and Mixers

Engines, Fans, and Blowers

Gas Turbines and Steam Turbines

Rotating Drum Screens

Electrical

Electrical Buildings

Power and Distribution Transformers

Generators and Switchgears

MCCs and Bus Ducts

Motors and Circuit Breakers

Panels and Junction Boxes

UPS, Battery, and Chargers

Cables, Insulators and Cable trays

Conduits, Fittings, and Electrical Heat Tracing

Lighting and HVAC

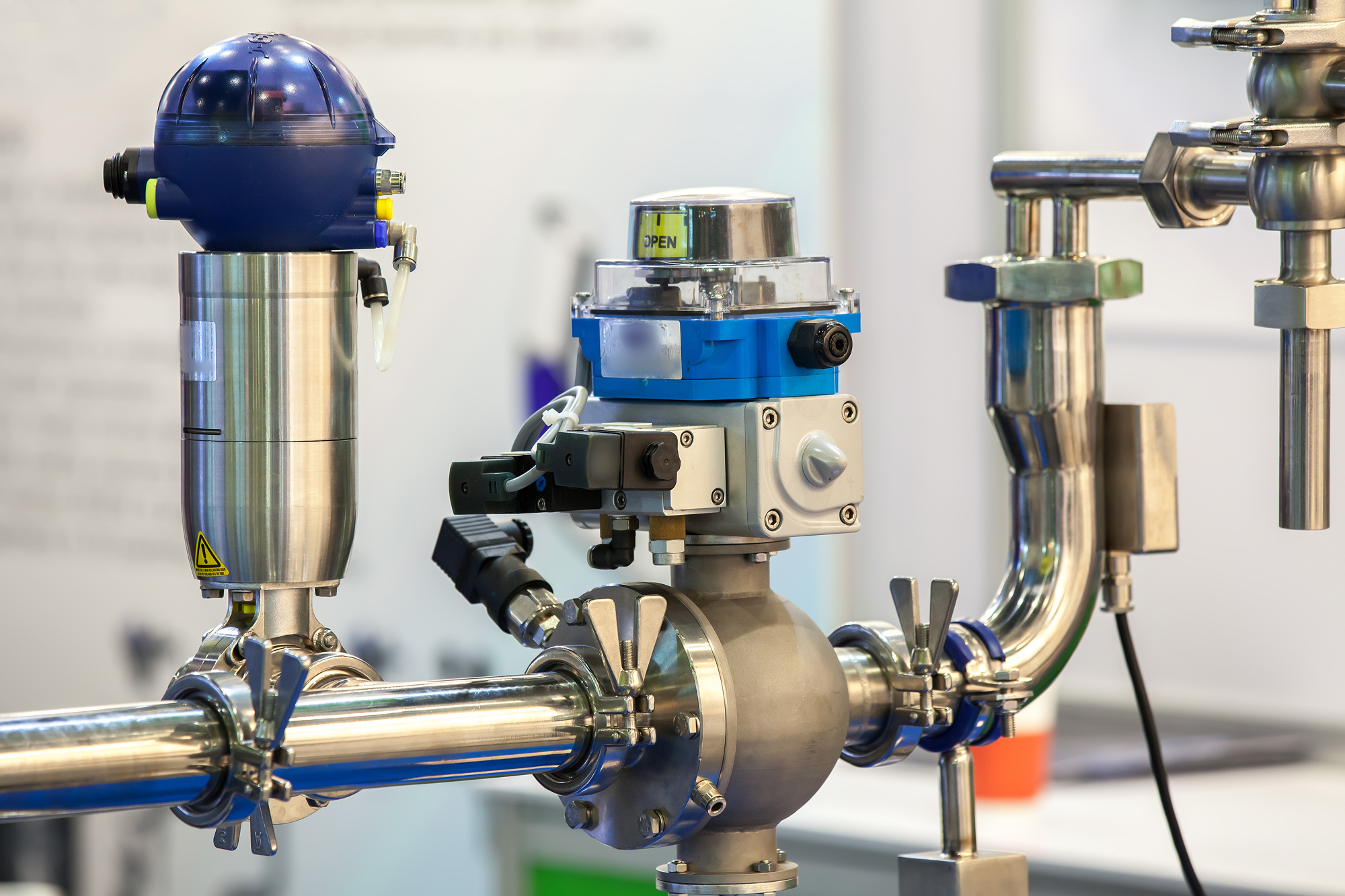

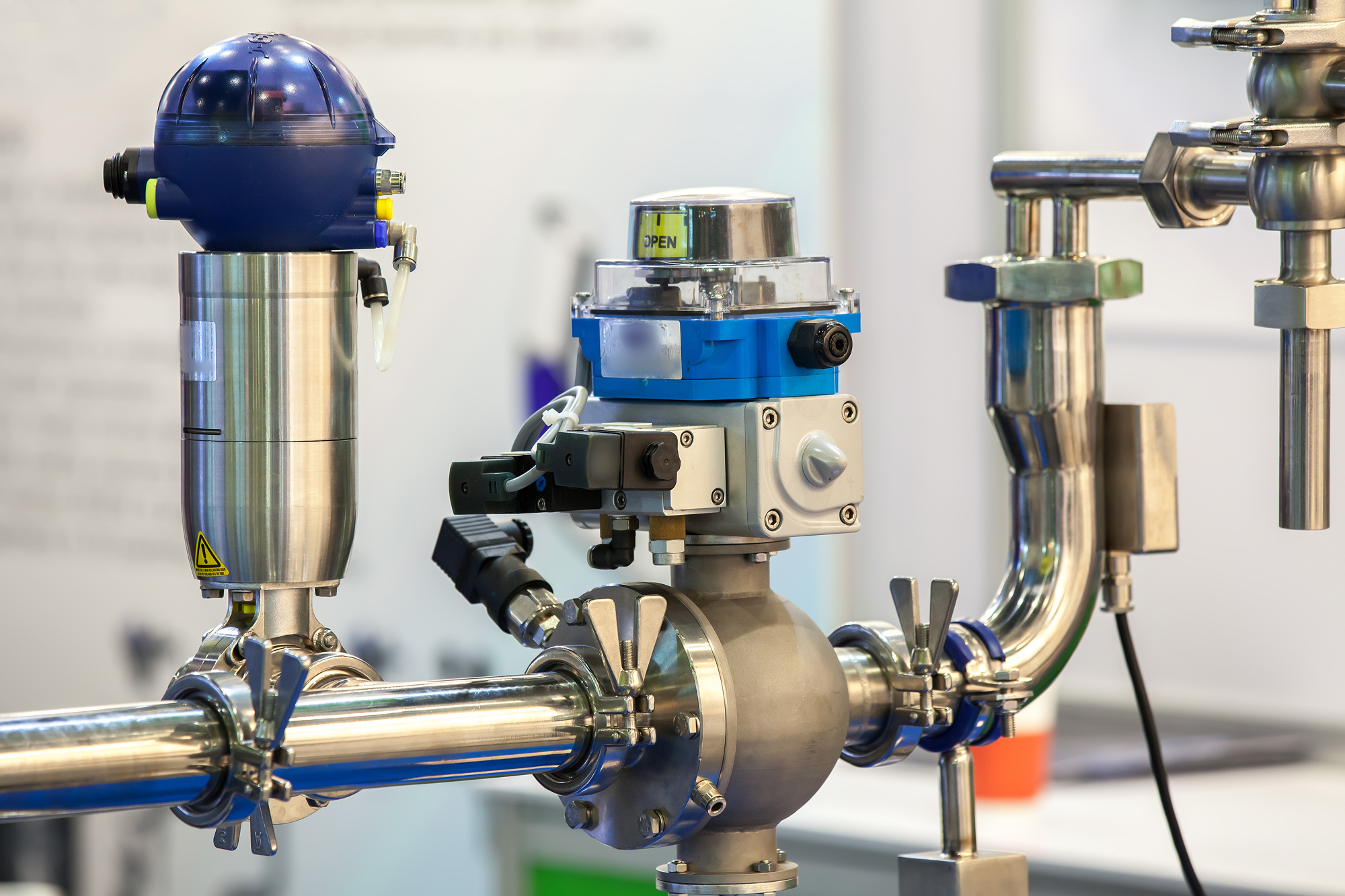

Instrumentation and Control

Valves and Panels

Actuators and Block Manifolds

Conductivity Meters and Transmitters

Regulators, Detectors, and Flow Meters

Gas Analyzers

Instrument Cables, Instrument tubes and Fittings

Level & Limit Switches

Gauges and Motor Operated Valves

Thermocouples, Thermowells, and Thermometers

Venturi Tubes

Lifting Equipment

Cargo Gear

Hoists, and Cranes

Breakage or issues of lifting equipment

Material compliance

Observation of any statutory requirements.

Industrial Valves

Ball Valves

Gate Valves

Plug Valves

Pressure Safety Valves

Butterfly Valves

Catalyst Tight Valves

Choke Valves and Cryogenic Flanged Gate

Globe and Check Valves

Double Block and Bleed Valves

Forged Gate and Gas Tight Valves

Skid-Mounted Units, Electrical-Mechanical

Boiler Water Treatment Units

Chemical Injection Packages

Desalination Plants

Dryer Packages

Oily Water Treatment Packages

Refrigeration Packages

Sanitary Water Treatment Packages

Raw Water Filters

Nitrogen Blanketing Systems